The Best ERP for the Manufacturing Industry

Get full control of all your manufactured products, the assets and your staff in one single platform.

Book your demo

Get full control of all your manufactured products, the assets and your staff in one single platform.

Book your demo

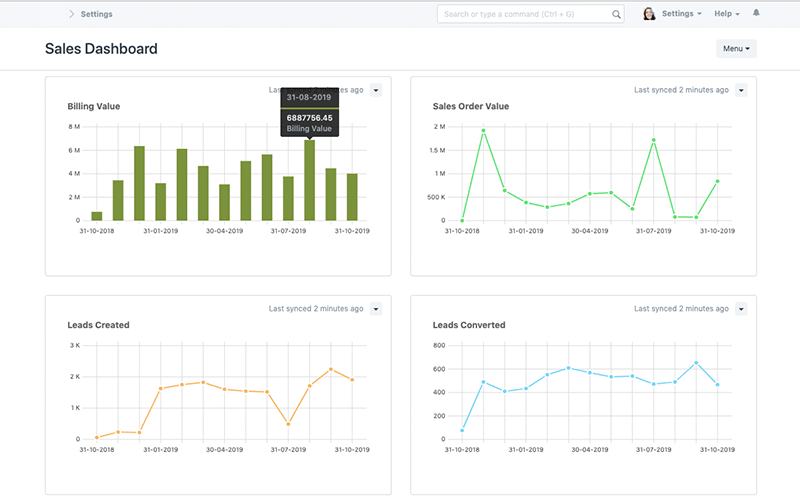

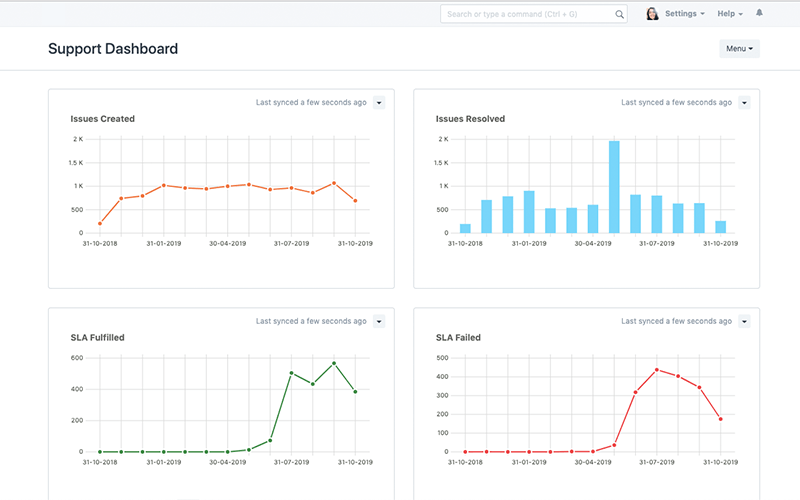

Provide an approach to the production process from all angles, integrating production planning and workshop with customer management, sales orders, inventory, purchases, accounting and financial reports. This will provide constant feedback in all departments.

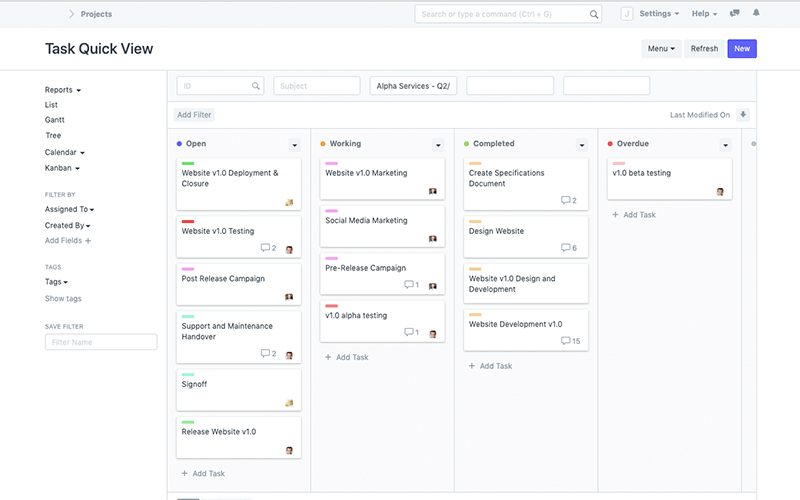

Control the arrival and departure of your employees, their performance and low production levels. Also keep a detailed follow-up of the work done for the manufacture of products, the assignment of employees for a project, the current status of each work order and other steps of the production process all on the same platform.

Use the outsourcing function of Paradiso ERP for manufacturing to outsource processes. It will have features such as the provision to supply raw materials. The valuation of finished products is the cost of raw materials sent abroad and the amount at which their services were purchased.

A reference variant is a version of a reference with different attributes such as sizes or colors. Suppose it produces t-shirts and comes in different sizes and colors such as small, medium, large and red, yellow, black. In Paradiso ERP, the shirt will be considered as a reference template and each of the variations will be a reference variant. Element attributes easily distinguish between these variants and can be based on size, color, shape, etc.

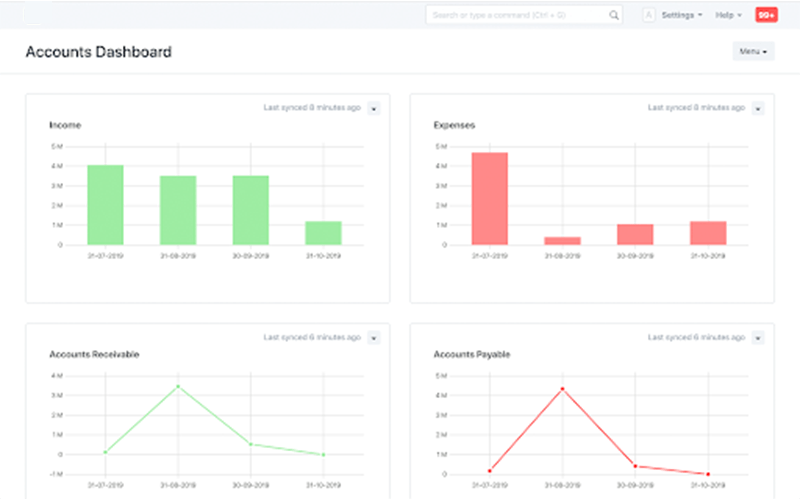

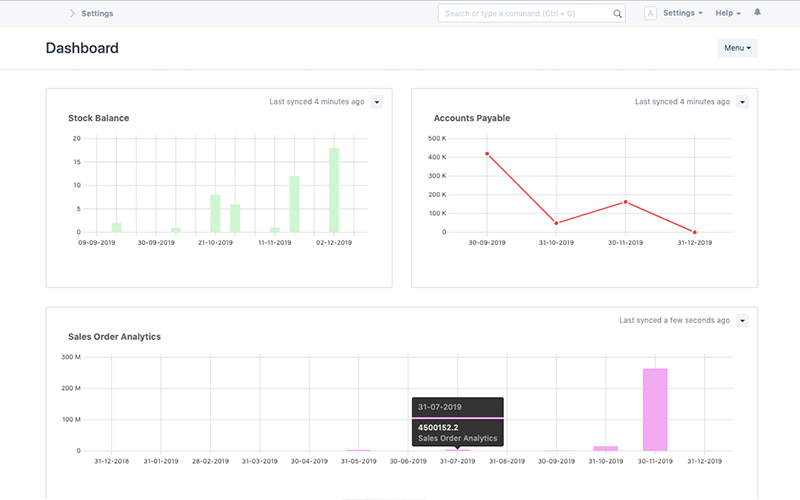

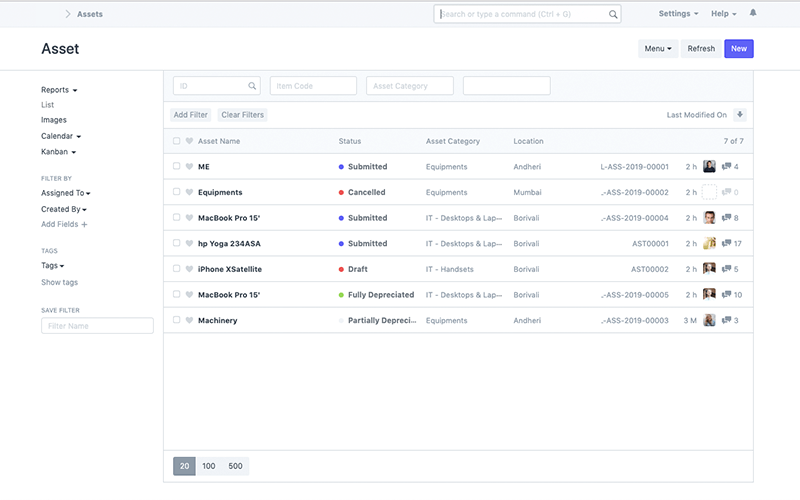

Integrated inventory so you have a real-time view of product availability, manage stock levels in various locations with warehouses, stock transfers, etc. Easily manage the quantity of products in stock, date of manufacture, expiration dates, times in stock, etc.

The acquisition of materials and production planning against sales orders or requests for materials enabled along with the provision to track material consumption to curb manufacturing costs and facilitate zero waste of resources.

Optimize the use of your workstations based on available resources for open production orders. Identify the bottlenecks at the workshop level and eliminate them by creating a capacity plan. You can maintain and manage planning schedules for a predefined period of time, for example, 30 days, 45 days, etc.

Minimize manufacturing costs and optimize resource allocation with Job Cards, Timesheets in all operations. You can track operational costs, resource costs and integrate these time sheets with the salary structure for uniform payroll processing as well.

With the Quick Stock Balance report, you can perform stock audits at the physical location to verify and validate the stock count in the warehouse and system. Simply scan the barcode with any device (a barcode scanner is not needed!) And start counting.

To avoid shortages, you can track the order level of an item. When the stock level falls below the order level, this retail ERP software will create an automatic material request for faster inventory replenishment, thereby reducing the possibilities of stock depletion.

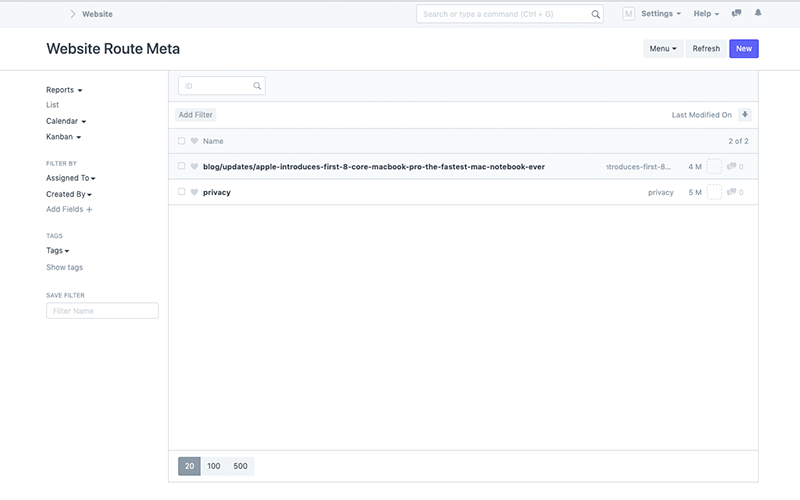

Assign important data specific to your business by adding custom fields on your forms. Customize the behavior of forms by automatically searching for values, hide fields based on user roles, create custom print formats, all without writing a single line of code. Create your own version of Paradiso ERP software for manufacturing.

Our ERP for Manufacturing can Integrate with your other Software Platforms

Book your demo

About us

Get in touch

Paradiso™ Software All Rights Reserved.